Day 15

Intro to Engineering

Allen Sam

7-3-18

Activities 7.3 and 7.4

7.3 Tolerances

1.

Study the drawings below to identify specified

tolerances.

a. Highlight

each dimension that has a tolerance associated with it using something like a

highlight marker.

b. Identify

the type of tolerance in each highlighted example by labeling each tolerance

dimension with one of the following: limit dimensions, unilateral tolerance, or

bilateral tolerance.

c. Label

each identified tolerance with a separate letter, A through Z.

d. Beginning

on a new page in your engineering notebook for each part, record the letter of

each tolerance identified on that part drawing, the type of tolerance, a short

written phase that describes the dimensional variation allowed for that

dimension, the tolerance (a number

representing the total allowed dimensional variation), and an explanation as to

why that particular dimension requires a tolerance. You may wish to duplicate

the following table in your notebook to organize your notes.

Part Name: __________adjustable rocker arm_________________

Letter

|

Tolerance Type

|

Written Explanation

|

Tolerance

|

Why?

|

|

Letter

|

Tolerance Type

|

Written Explanation

|

Tolerance

|

Why?

| |

| gives the ranges of what the dimension can be | .005 | The hole needs to be extremely fit with the insert piece | |||

| D | bilateral | can vary in size either bigger or smaller | .1 |

|

Letter

|

Tolerance Type

|

Written Explanation

|

Tolerance

|

Why?

|

Letter

|

Tolerance Type

|

Written Explanation

|

Tolerance

|

Why?

|

2.

Consider the adjustable rocker arm represented

in the drawing above. An axle is to pass through the smallest hole. The

manufacturer is considering buying bar stock for the axle that is manufactured

according to the following drawing using the same general tolerances as those

specified on the Rocker Arm Drawing. Answer the following questions and SHOW

YOUR WORK.

a. What

is the tolerance (the acceptable amount of dimensional variation) for the

diameter of the rod?

b. What

is the tolerance for the rod length?

c. Is

the fit between the rod and the hole a clearance fit, interference fit, or

transition fit? Explain your answer.

A clearance fit must have the part touching, an interference fit needs to have the external dimension be bigger than the internal dimension, and a transition fit has to have a specific tolerance.

d. What

is the allowance between the rod and the smallest hole?

.0025 +.0025=.005 inches

e. If

the design of the assembled machine requires that the rod is sized such that

the actual clearance between the rod and the hole is never greater than 0.005

inches, will the current rod design meet the requirement? Explain.

no, because both pieces can have total tolerance of more than .005 inches.

f.

The machine specification requires that the rod

is no longer than 3.025 inches and no shorter than 2.955 in.

·

Let L represent the actual length of the rod.

Write the length constraint as a compound inequality.

2.955≤ L≤ 3.025

·

Will the stock rods always meet the length

constraint? Explain.

yes, because the limiting tolerances will fit the inequality of the variation.

g. If

the stock rods do not always meet the machine specifications for rod length,

how can the manufacturer alter the rod part drawing such that the rod length

will always conform to the specifications?

The rod makers can lower the tolerance of the rod length.

3.

Design a rod that will have an interference fit

so that the allowance (the maximum interference) is 0.010 with the center hole

in the Rocker Arm and the tolerance on the rod diameter is .002. Sketch a

section view of your rod design below. Be sure to specify the tolerance in the

diameter dimension of your design.

4.

Consider the axle pin and the body of the

Automoblox vehicle (shown below). The axle is designed to remain inserted into

the body of the vehicle so that it cannot be removed by a child.

a. What

type of fit would you recommend for the axle and body? Why?

I would have an extremely small interference fit because you want the small piece to fit as tight as possible to the hole so the child can't take it out.

b. Assume

an interference fit is used and that the ideal interference between the axle

and the hole in the body of the vehicle is 0.005 inches. However, the

interference can increase to as much as .010 without damage to the parts. With

the addition of glue to help adhere the two pieces, an interference of .002 can

be used successfully. Assume that the specified diameter of the axle is 0.300

inches as shown on the pictorial above. On the images above indicate your

recommendation for:

·

the specific tolerance to the axle diameter

dimension\

.300 +_ .001

.300 +_ .001

·

the diameter and associated tolerance for the

hole in the bed

.3005+_ .002

.3005+_ .002

c. Calculate

the following for the exterior axle pin diameter using your suggested dimension

tolerances. SHOW YOUR WORK.

Specified dimension:

0.300 inches

Upper Limit:

___.300+.001=.301inches_____________

Lower Limit:

______.300-.001=.299inches_________

Tolerance: _______.002inches__________

d. Calculate

the following for the diameter of the hole in the body using your dimensioned

part drawing. SHOW YOUR WORK.

Specified Dimension:

______.3005__________ (if applicable)

Upper Limit:

________.3005+.002=.3025inches________

Lower Limit:

____.3005-.002=.2085inches___________

Tolerance: ____.004inches_____________

e. Calculate

the allowance between the hole and the axle pin diameter based on your

recommended dimensions and tolerances. SHOW YOUR WORK.

.004+.006=.006iches

5.

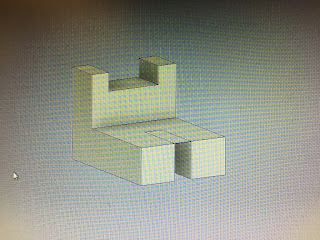

Open the drill block drawing file that you

created in Activity 7.2 Sectional Views. The drill block drawing is shown

below.

6.

Consider the drill block from the question

above.

a. If the detail drawing used chain dimensioning to locate the holes along the 5 in. dimension as shown in the image below (and therefore the tolerances are additive), what would be the upper and lower limit of the dimension from the left edge to the center of the 0.25 inch diameter hole on the right (see below) assuming general tolerances apply?

.75+_.05 = 1+_.05 + 1.25+_.05 + 1.25+_.05= 4.55 inches to 4.95 inches

b. What is the upper and lower limit of the dimension from the left edge to the center of the 0.25 inch diameter hole in the drawing you created (using datum dimensioning) assuming general tolerances apply?

4.75+_.05= 4.7 and 4.8 inches

Conclusion

1. Why

do engineers place tolerances on dimensions?

We place tolerances in dimensions because manufacturing is never perfect and there needs to be a limit for how variation a dimension can have when making a part.

2.

What are the three types of tolerances that

appear on dimensioned drawings?

There are bilateral tolerances, unilateral tolerances, and limiting tolerances.

3.

What is the difference between a general and a

specific tolerance, and how can you tell the difference on a drawing?

A general tolerance is one that will apply if no specification is applied, and a specific tolerance is assigned for only a certain dimension. A general tolerance will be located in the general tolerance chart while specific dimensions are at the specific annotation for the dimension.

It is a type of constrain where you may not want something to be completely flush with the other chosen part of an object.

A mate flush connects the two faces together while the flush constrain aligns the two faces so that they are collinear

I would use a mate constraint because it connects the inside of the hole with the outside of the pin. This removes horizontal and vertical degrees of movement and only the z axis is still allowed.

You can use a tangent constraint to make a face touch with another point you choose. The tangent constraint removes the vertical movement of the part.

Activity 7.4

Conclusion

1. What

is an offset and how is it used?

2.

What is the difference between a mate and flush

constraint?

3.

What constraint would you use to place a pin

inside a hole? Which degrees of freedom does this constraint remove? Use a

sketch to define the degrees of freedom.

4.

Describe a situation in which you would use a

tangent constraint. Which degrees of

freedom does a tangent constraint remove?

Use a sketch to define the degrees of freedom.

5.

What is a subassembly? How is it useful in the

assembly of a complex product that involves multiple parts?

A subassembly is a part that is a part of a bigger assembly. It is useful to have completed sub assemblies because you can rotate them correctly.

Comments